These vehicles are ideal to collect great waste volumes, and can be used even in very large cities, since they can also be loaded with waste collected by smaller vehicles. Their load capacity ranges from 14 to 30 cubic metres.

Характеристики

- объем от 14 до 30 кубических метров

- подходит для крупных городов

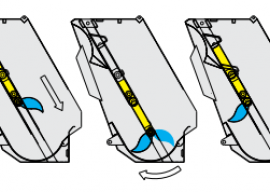

Compaction cycle with articulated single blade.

The compactioon system has an hydraulically operated articulated single blade which is moved to collected and compress waste. The high cycle speeds ensure that large amounts of material can be handled even when arriving continuously from bin turn and bucket turn devices or satellite vehicles. A sturdy tip-up tailgate can be lowered to facilitate manual loading. Types of waste may include dry, paper, cardboard, plastic, glass, tins, organic and vegetal materials. The system can operate in manual (for independent control of every movement), continuous automatic, single cycle automatic and synchronised modes (the cycle is activated by the bin turn device).

The ZENIT M1 - M2 - M3 range of attachment supplied by TECNOINDUSTRIE MERLO S.p.A. comprises rear load mini-compactors with hood, unloading by means of an expulsion bulkhead, fitted with an articulated single-blade compaction system with a rotary blade and a slide running on straight guideways. The rear part of the attachment, on the tip-up hatch, is where the bin pick-up, listing and emptying system can be mounted in a central position (Optional).

The attachment is compliant with Machinery Directive 2006/42/CE and is certified by an independent

| модель | M1

|

M2

|

M3

|

||

|---|---|---|---|---|---|

|

|

ZENIT 14 | ZENIT 16 | ZENIT 23 | ZENIT25 | ZENIT 30 |

| Dump body volume (m3)

|

14 | 16 | 23 | 25 | 30 |

| Volume of loading mouth (m3)

|

1.7 | 1.7 | 2.6 | 2.6 | 3.5 |

| Internal load mouth width (mm)

|

2200

|

2200

|

2200

|

2200

|

2200

|

| Total mass on ground (kg)

|

15,000 - 18,000

|

26,000

|

26,000

|

26,000 - 40,000

|

|

| Chassis axles (n.)

|

2 | 2 | 3 | 3 | 4 |

| Compaction system

|

Articulated single loader blade

|

||||

| Compaction cycle

|

Automatic / Continuous / Synchronised

|

||||

| Filling speed (m3/min)

|

4.5

|

4.5

|

5.5

|

5.5

|

7.5

|

| Compaction ratio selection

|

Electronic from cab | ||||

| Adjustable compaction ratio

|

From 2:1 to 6:1

|

||||

| Discharge system

|

Expulsion bulkhead

|

||||

| Merlin command and control system

|

●

|

●

|

●

|

●

|

●

|

| Bin turn device with Shaker function

|

○

|

○

|

○

|

○

|

○

|

| Bucket turn device with hydraulic stabilisers

|

○

|

○

|

○

|

○

|

○

|

| Acceptance of waste from satellite vehicles

|

●

|

●

|

●

|

●

|

●

|

| Rear infra-red camera with colour monitor in the cab

|

●

|

●

|

●

|

●

|

●

|

| Camera for observation inside hopper

|

○

|

○

|

○

|

○

|

○

|

| Rear white LED beacon

|

●

|

●

|

●

|

●

|

●

|

| Flashing yellow LED beacons

|

●

|

●

|

●

|

●

|

●

|

| Rear plaƞ orm for operators

|

○

|

○

|

○

|

○

|

○

|

| Blade and brush holder

|

●

|

●

|

●

|

●

|

●

|

| Load weighing device

|

○

|

○

|

○

|

○

|

○

|

| Bin identification system

|

○

|

○

|

○

|

○

|

○

|

● в стандартной комплектации

○ опционально